Positioner Accuracy, Precision, and Resolution

What They Mean and Why They Matter

Positioners are integral to imaging systems, as their ability to accurately and efficiently aim at targets can make the difference between hitting the target on the first try or wasting precious time searching for it. In some cases, this can even lead to mission failure or, at the very least, significant frustration.

Manufacturers often quote specifications like accuracy, precision, and resolution to describe how well their positioners can target an object. However, many people mistakenly use these terms interchangeably, when in fact, they have distinct meanings.

Defining Key Terms

- Accuracy: The degree to which a measurement is close to the true or target value.

- Precision: The degree to which repeated measurements yield the same result.

- Resolution: The smallest possible increment of measurement that can be made.

Of these, resolution is the easiest concept to grasp. It refers to the smallest detectable measurement that can be made by an instrument. For instance, consider an analog wristwatch with a second hand. If each second is marked on the dial, the resolution is 1 second. Some people might argue that the resolution is even finer (0.5 seconds), based on how closely the second hand can be observed between marks. However, you wouldn’t rely on such a watch for measurements down to a hundredth of a second—this level of precision is beyond its resolution. In short, resolution is simply the smallest measurable unit an instrument can detect.

Positioner Resolution

In positioners, resolution is often associated with the encoder (or resolver) that measures angular motion. Unfortunately, manufacturers sometimes mislead customers by reporting encoder resolution as either precision or even accuracy, which can create confusion.

The key issue is where in the drive system the encoder is measuring. It could be attached to the motor’s output shaft, a separate belt/pulley system, or directly coupled to the positioner’s output. Without knowing the specific location of the encoder and understanding the entire drivetrain’s role in error accumulation, you cannot equate encoder resolution directly to system performance.

While encoder resolution represents the theoretical maximum precision, it doesn’t fully account for real-world factors like mechanical tolerances and control system limitations. In essence, it provides an upper bound on what the system’s precision could achieve, but it’s not a guarantee that this precision will be realized in practice.

Accuracy vs. Precision: A Classic Analogy

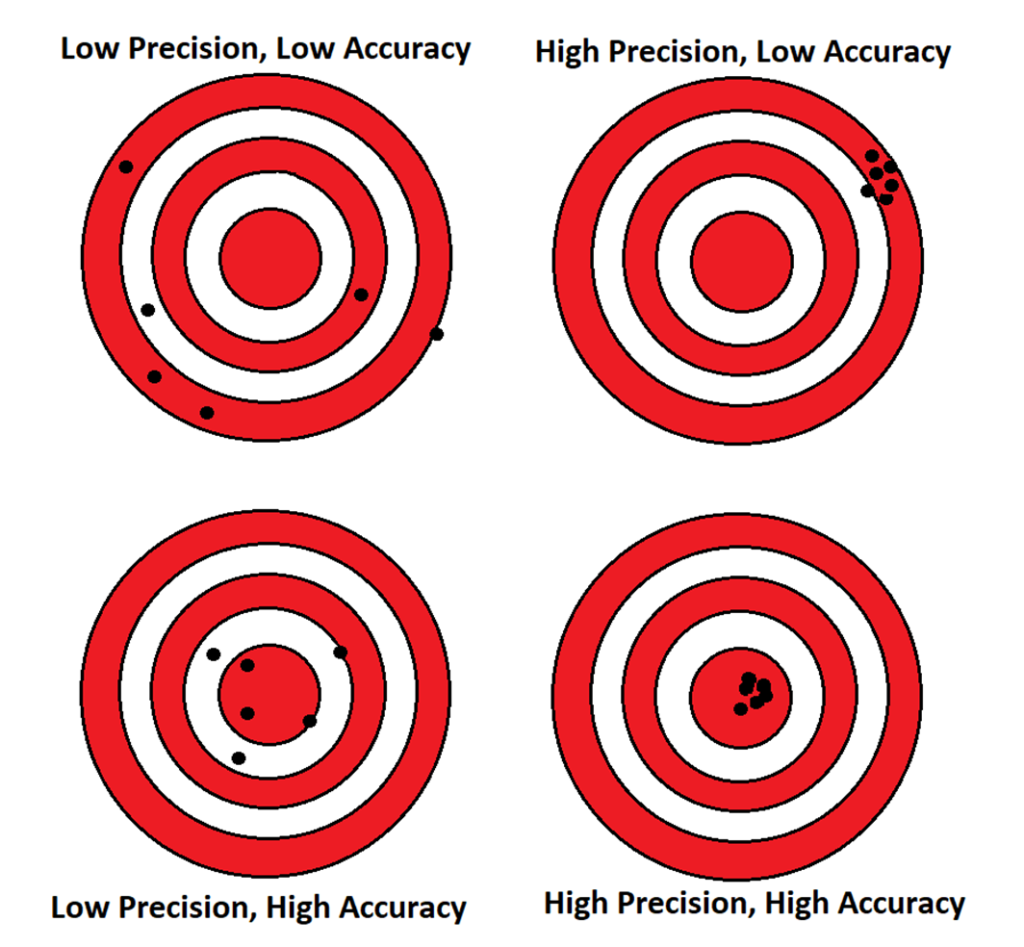

To better understand accuracy and precision, let’s look at a classic analogy from target shooting. In Figure 1, we can see several groups of shots on a target, each representing different distributions of accuracy and precision:

- Precision: The shots are tightly grouped together, indicating that repeated attempts yield consistent results.

- Accuracy: The grouping of shots is near the center of the target, showing that the measurements are close to the ideal target point.

This example illustrates that precision and accuracy are independent of each other. A shooter can have one without the other, or both together. Achieving both in an imaging system is ideal.

Positioner Accuracy and Precision

Translating this analogy to positioners, precision refers to how small a repeatable movement can be made. This is crucial for tasks like centering a target in the field of view. The more precise the positioner, the smaller the adjustments it can make, improving the likelihood of successfully finding or tracking the target.

On the other hand, positioner accuracy represents the system’s ability to correctly aim at a target. For example, when preset positions are used (e.g., aiming at a road junction, a gate, or a distant mountain pass), accuracy ensures that the system lands on the right spot. This is particularly important for long-range systems, where even a slight error in aiming could result in missing the target by a significant margin.

Accuracy is also critical in tracking systems (such as optical or radar tracking), where fine, accurate movements are essential for smooth and seamless tracking. A precise and accurate positioning system ensures that the target is continuously locked onto, without abrupt jumps or errors.

Summary

- Accuracy refers to how well the measurements align with the true target.

- Precision measures how consistently you can achieve the same result with repeated measurements.

- Resolution defines the smallest measurable increment in the system.

When evaluating a positioner, it’s crucial to scrutinize the reported numbers. Encoder resolution often gets confused with precision or accuracy, but it only represents a theoretical upper limit on precision. It doesn’t necessarily reflect the full system’s performance, and it provides no insight into accuracy.

For optimal performance, ensure that your positioner excels in both accuracy and precision. Be mindful of how manufacturers define and report these terms, and always consider the system as a whole rather than focusing solely on individual components like encoders.